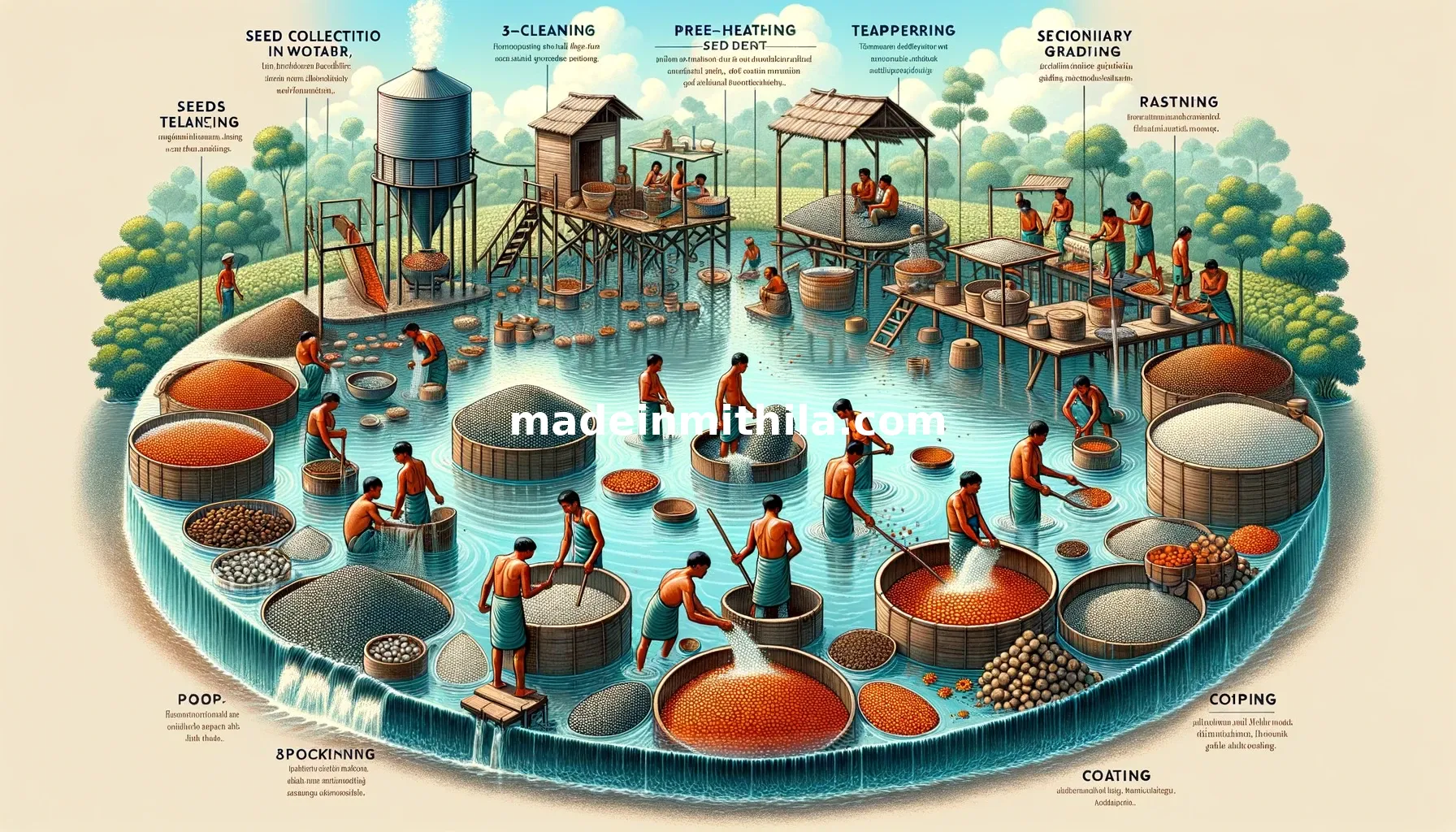

From Pond to Packet: The Intricate Process of Makhana Production

Makhana, or foxnut, is a superfood that has captured the attention of health enthusiasts worldwide. The journey of Makhana from the ponds of Mithila to your packet involves several meticulous steps. This blog takes you through each stage of the Makhana production process, highlighting the care and precision involved.

1. Seed Collection

The journey begins with the careful collection of Makhana seeds. Farmers wade through the water bodies, collecting the mature seeds that have fallen to the bottom. This process is labor-intensive and requires skill and patience.

2. Seeds Cleaning

Once collected, the seeds undergo thorough cleaning to remove mud, dirt, and other impurities. This step ensures that only the best quality seeds move forward in the production process.

3. Makhana Grading

The cleaned seeds are then graded based on size and quality. Grading is essential to ensure uniformity in the final product. Larger seeds are typically preferred for their better popping quality.

4. Pre-Heating

Graded seeds are pre-heated to remove any remaining moisture. This step is crucial as it prepares the seeds for tempering and roasting, ensuring they pop perfectly.

5. Seed Tempering

Tempering involves soaking the seeds in water for a specific duration. This process softens the seeds and enhances their ability to pop. The duration and conditions of tempering are carefully controlled to achieve the desired results.

6. Roasting of Seeds

Tempered seeds are roasted in a pan or oven at a specific temperature. Roasting is a critical step that affects the texture and flavor of the Makhana. The seeds need to be roasted evenly to ensure they pop correctly.

7. Popping of Seeds

The roasted seeds are then popped. This is a skillful process where the seeds are subjected to high heat, causing them to pop open. Popping is done in small batches to ensure even popping and to maintain quality.

8. Grading Again

After popping, the Makhana is graded once more. This secondary grading ensures that any seeds that did not pop properly are removed. Only perfectly popped Makhanas make it to the next stage.

9. Seasoning/Coating

The popped and graded Makhana is then seasoned or coated with various flavors. This can include anything from a light salt seasoning to more elaborate coatings like caramel or spices. Seasoning adds to the flavor profile of the Makhana, making it a delightful snack.

10. Packaging

Finally, the seasoned Makhana is packed in airtight containers to maintain freshness and crunchiness. Packaging is done under hygienic conditions to ensure the product reaches consumers in the best possible quality.

Conclusion

The meticulous process of Makhana production, from seed collection to packaging, ensures that you receive a product of the highest quality. Each step is carried out with precision and care, reflecting the dedication of the farmers and producers in the Mithila region.

By choosing Makhana from MadeInMithila.com, you are not only indulging in a healthy and delicious snack but also supporting sustainable farming practices and the local community.

For more information or to place an order, contact us at:

- Mobile: +91-8800445486

- WhatsApp: Click Here to Chat

- Email: aabmakhana@gmail.com